Czy modyfikacja statecznika w śmigłowcu serii Robinson rzeczywiście jest konieczna?

- Home

-

Aviation store

-

Aircraft parts

- Aircraft parts

- Batteries

- To engine

-

Fasteners

- Temperature recorders

- Aviation lighting

-

Robinson R22

- Avionics

- Doors and windows

- Hull

- Controlling the flight

- Environmental control

- Ground handling

- Lighting

- Parking and storage

- Chassis

- Servicing

- Engine

- Special tools

- Motor control

- Instrument system

- Fuel system

- Plates and markings

- Paving and balancing

- Electrical system

- Main Rotor Drive System

- Tail rotor drive system

- Engine oil system

- Weight and balance

- Main rotor

- Tail rotor

- Equipment

-

Robinson R44

- Autopilot

- Avionics

- Doors and windows

- Hull

- Controlling the flight

- Environmental control

- Hydraulics

- Ground handling

- Lighting

- Parking and storage

- Chassis

- Servicing

- Engine

- Special tools

- Motor control

- Instrument system

- Fuel system

- Plates and markings

- Paving and balancing

- Electrical system

- Main Rotor Drive System

- Tail rotor drive system

- Engine oil system

- Weight and balance

- Main rotor

- Tail rotor

- Equipment

-

Robinson R66

- Autopilot

- Avionics

- Doors and windows

- Hydraulics

- Hull

- Environmental control

- Controlling the flight

- Ground handling

- Lighting

- Parking and storage

- Chassis

- Servicing

- Engine

- Special tools

- Motor control

- Instrument system

- Fuel system

- Plates and markings

- Paving and balancing

- Electrical system

- Main Rotor Drive System

- Tail rotor drive system

- Engine oil system

- Weight and balance

- Main rotor

- Tail rotor

- Equipment

- Aviation chemistry

- Cleaning cloths and rags

- Paints and primers, painting accessories

- Abrasive sheets and fleeces

- Oils and greases

- Tools

- Aviation accessories and gadgets

-

Aircraft parts

- Lycoming engines

- SERVICE R22 R44 R66

- Helicopter Transport

- Blog

- About us

- New products

Latest posts

-

Czy modyfikacja statecznika w śmigłowcu serii Robinson rzeczywiście jest konieczna?Read more

Czy modyfikacja statecznika w śmigłowcu serii Robinson rzeczywiście jest konieczna?Read more -

FAA Approval to Double the Life of Select Robinson R66 Components09/05/2024Read more

FAA Approval to Double the Life of Select Robinson R66 Components09/05/2024Read moreRobinson Helicopter Company (RHC), the world's leading manufacturer of civilian helicopters, has received FAA...

-

50th Anniversary of Robinson Helicopter Company06/20/2023Read more

50th Anniversary of Robinson Helicopter Company06/20/2023Read moreToday, June 20, 2023, marks 50 years since Robinson Helicopter...

-

Can the oil in an aircraft piston engine be refilled with another brand of oil?11/21/2022Read more

Can the oil in an aircraft piston engine be refilled with another brand of oil?11/21/2022Read moreVery often pilots ask us if they can use another brand of oil, e.g. for a top-up.The answer is...

-

Is the Robinson R66 helicopter safer than the R44?05/13/2022Read more

Is the Robinson R66 helicopter safer than the R44?05/13/2022Read moreIs the Robinson R66 helicopter safer than the R44?

-

FAA approves stick guard11/15/2021Read more

FAA approves stick guard11/15/2021Read moreThe safety-enhancing stick guard is FAA approved for...

-

Robinson R44 Service Bulletin SB-108 also became an Airworthiness Directive (FAA AD 2021-19-8)09/09/2021Read more

Robinson R44 Service Bulletin SB-108 also became an Airworthiness Directive (FAA AD 2021-19-8)09/09/2021Read moreRobinson R44 Service Bulletin SB-108 is now an FAA AD!

-

How to properly clean plastic windows in a helicopter or plane04/11/2021Read more

How to properly clean plastic windows in a helicopter or plane04/11/2021Read moreWith the summer season approaching, it is worth taking care of aircraft windows.As we know, the summer season is a...

-

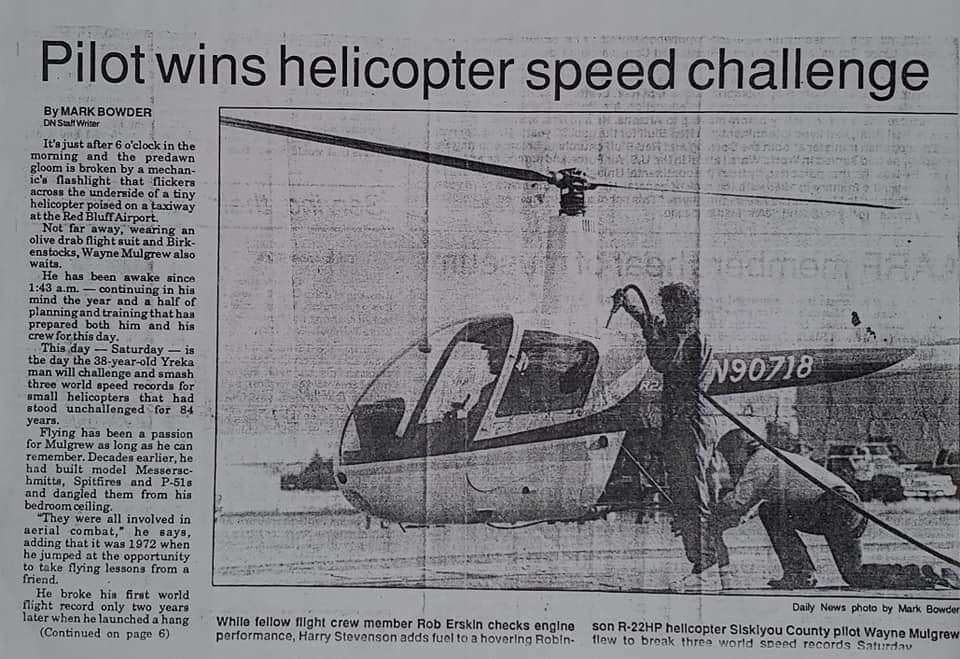

World record with Robinson R2202/15/2021Read more

World record with Robinson R2202/15/2021Read moreOn September 22, 1990, in Red Bluff, California (USA) the "speed challenge" took place - an attempt to set a speed...

-

Robinson R22 / R44 / R66 On-Board Camera02/11/2021Read more

Robinson R22 / R44 / R66 On-Board Camera02/11/2021Read moreRobinson's cockpit video camera debuted at last year's Heli Expo 2020 - it is now an optional extra on R22/R44...

Blog categories

Search in blog

Are You Unconsciously Reducing Your Helicopter's Efficiency and Shortening the Life of Your Blades?

Blade Cleaning and Maintenance..?

We have noticed that many of our customers do not take care of their main rotor blades...

When inspecting the blades, our first task is usually to clean them....?♂

sticky insects, pollen, grass, etc. to accumulate mainly on their leading edges.

Cleaning, waxing or protecting the blades with an anti-corrosion agent has a very positive effect on their efficiency.

On the Robinson R22, dirty blades can take away as much as 1.5 inches from the manifold pressure gauge.

Keeping the blades clean is an easy and simple way to restore the efficiency of the helicopter.

Washing and maintaining blades also has a very positive effect on corrosion damage.

Microscopic holes are then created on the paint surface, exposing small areas of the aluminum coating

subject to the adverse effects of nature.

This causes corrosion that causes serious damage, so waxing the blades is recommended to prevent this.

Thanks to this treatment, the wax will fill in the blemishes and also prevent corrosion.

The line where the joint is joined must be painted in such a way that it properly protects the joining material.

The aircraft paint / epoxy coating "propeller" from TEMPO is ideal for this purpose, its task is to provide additional adhesion and abrasion resistance needed to protect the propellers from corrosion and use.

Related posts

-

HOW TO UNLOCK A BURNED SCREW?

Posted in: Helimot11/02/2020HOW TO UNLOCK A BURNED SCREW?Read more

HOW TO UNLOCK A BURNED SCREW?

Posted in: Helimot11/02/2020HOW TO UNLOCK A BURNED SCREW?Read more -

NEW ROBINSON WINDOWS. DOES THIS MEAN THAT THE STANDARD WINDOW IS NOT RESISTANT TO ANY BIRD IMPACT?

Posted in: Helimot11/17/2020Robinson's impact-resistant windshields improve bird strike protection. Robinson has introduced...Read more

NEW ROBINSON WINDOWS. DOES THIS MEAN THAT THE STANDARD WINDOW IS NOT RESISTANT TO ANY BIRD IMPACT?

Posted in: Helimot11/17/2020Robinson's impact-resistant windshields improve bird strike protection. Robinson has introduced...Read more -

Everything you need to know about vibration in a helicopter

Posted in: Helimot11/18/2020Everything you need to know about vibration in a helicopter...Read more

Everything you need to know about vibration in a helicopter

Posted in: Helimot11/18/2020Everything you need to know about vibration in a helicopter...Read more -

WHAT IF I EXCEED THE MANIFOLD PRESSURE LIMIT?

Posted in: Helimot11/19/2020Have you exceeded your manifold pressure limit? What now? Do I need an inspection?No, there is no need to call a...Read more

WHAT IF I EXCEED THE MANIFOLD PRESSURE LIMIT?

Posted in: Helimot11/19/2020Have you exceeded your manifold pressure limit? What now? Do I need an inspection?No, there is no need to call a...Read more -

FAA APPROVES LYCOMING ELECTRONIC IGNITION SYSTEM FOR ROBINSON HELICOPTERS

Posted in: Helimot11/17/2020R22 and R44 helicopters purchased after January 15, 2020 will be equipped with...Read more

FAA APPROVES LYCOMING ELECTRONIC IGNITION SYSTEM FOR ROBINSON HELICOPTERS

Posted in: Helimot11/17/2020R22 and R44 helicopters purchased after January 15, 2020 will be equipped with...Read more

Leave a comment